CUSTOMER NOTICE: WE ARE CLOSED on Mondays and Tuesdays. All orders will ship Wednesday to Friday. Phones, and email, will also only operate on these days. If you need to contact us about an order, or anything else, you can use our WhatsApp number: 07985497351

Tarty Bikes RD Range

We've been working away the past few months to design and test some brand-new products, made specially for us, to fill what we feel are some gaps in the current market. With prices continuing to soar generally, and many once popular trials products not easily available any more, we've been keen since taking ownership of the business to bring our own range of products to market that are sensibly priced, and offer practical, performance enhancements to your bike!

We know that many brands of the 'golden era' of trials are sorely missed for their huge range of parts and useful problem solvers. RD parts are our way of making these parts available again with our signature eye for detail and at a price that makes them affordable to every rider.

Each part has been designed by Tarty Bikes founder, Adam Read, using his huge depth of trials knowledge and design skills to create a range of products that not only work brilliantly, but also have practical considerations for the sport of trials. Whether that's a wide range of compatibility, ease of modification or adjustability.

We hope the RD range will continue to grow, and that you find what you've been looking for! If you have any suggestions on parts you would like us to make, please get in touch and let us know.

Adam has written a short piece on his thought process behind the design, materials and concepts behind the RD range, read on to find out more.

"When Ben & Charlie came to me and said they wanted to develop a range of Tarty Parts, and asked if I wanted to help – the answer was of course a big YES! I’ve always loved this stuff. Even back at university I classed CAD (Computer Aided Design) as a hobby rather than a module, so being able to stretch my grey matter again has been a lot of fun.

The idea was to create a small range of parts that were really affordable, totally functional and a bit oldskool in terms of looks and design, while filling gaps in the market or improving on existing products. Working with a local company (just over half a mile from the warehouse!) has been super useful, as we could do small prototype batches and iterate / tweak until we were happy with everything. There is a lot of detail gone into all of the designs which isn't immediately apparent on first glance, but through a combination of doodling, drawing up, revising, measuring, fitting and testing, we are really proud to have released what we think are some very neat products.

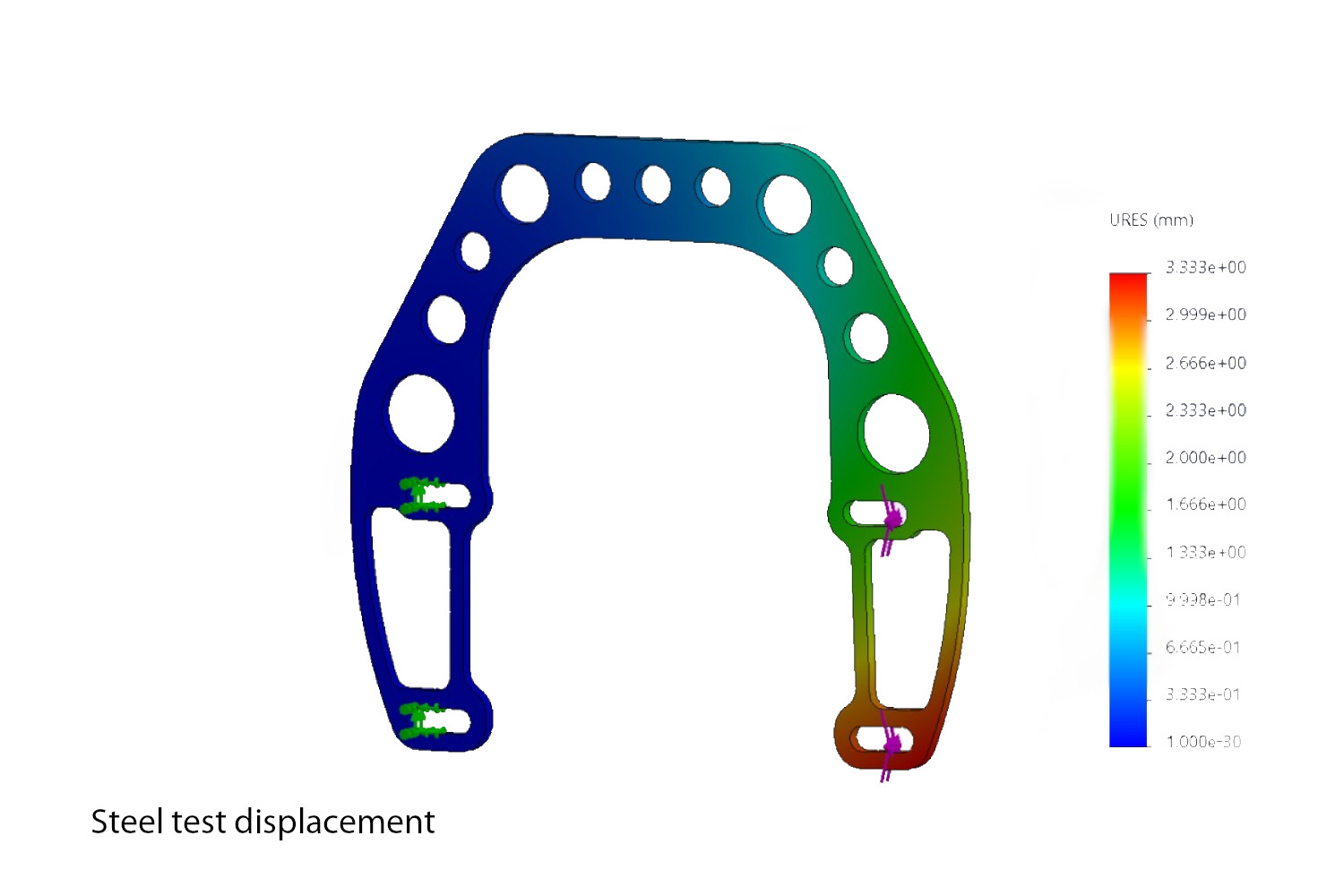

We chose laser cutting as it allows small production runs to be done, and stainless steel as it’s an often overlooked material for functional parts. Steel is relatively heavy per unit volume – a lump of stainless is around 3 times heavier than the same size piece of aluminium – but it is also around 3 times as stiff and 3 times as strong. We are used to seeing a lot of bike parts made in aluminium, so the eye can be a bit deceiving at first – but a 3mm thick stainless booster is around the same stiffness as a 9mm aluminium one, for example.

This has been tested with FEA (Finite Element Analysis) on selected products, optimising shape and design to cope with the loads that they are subjected to. This of course needs confirming in the real world, where Ben has been giving the full range a good going over (especially that bash ring eh! Haha).

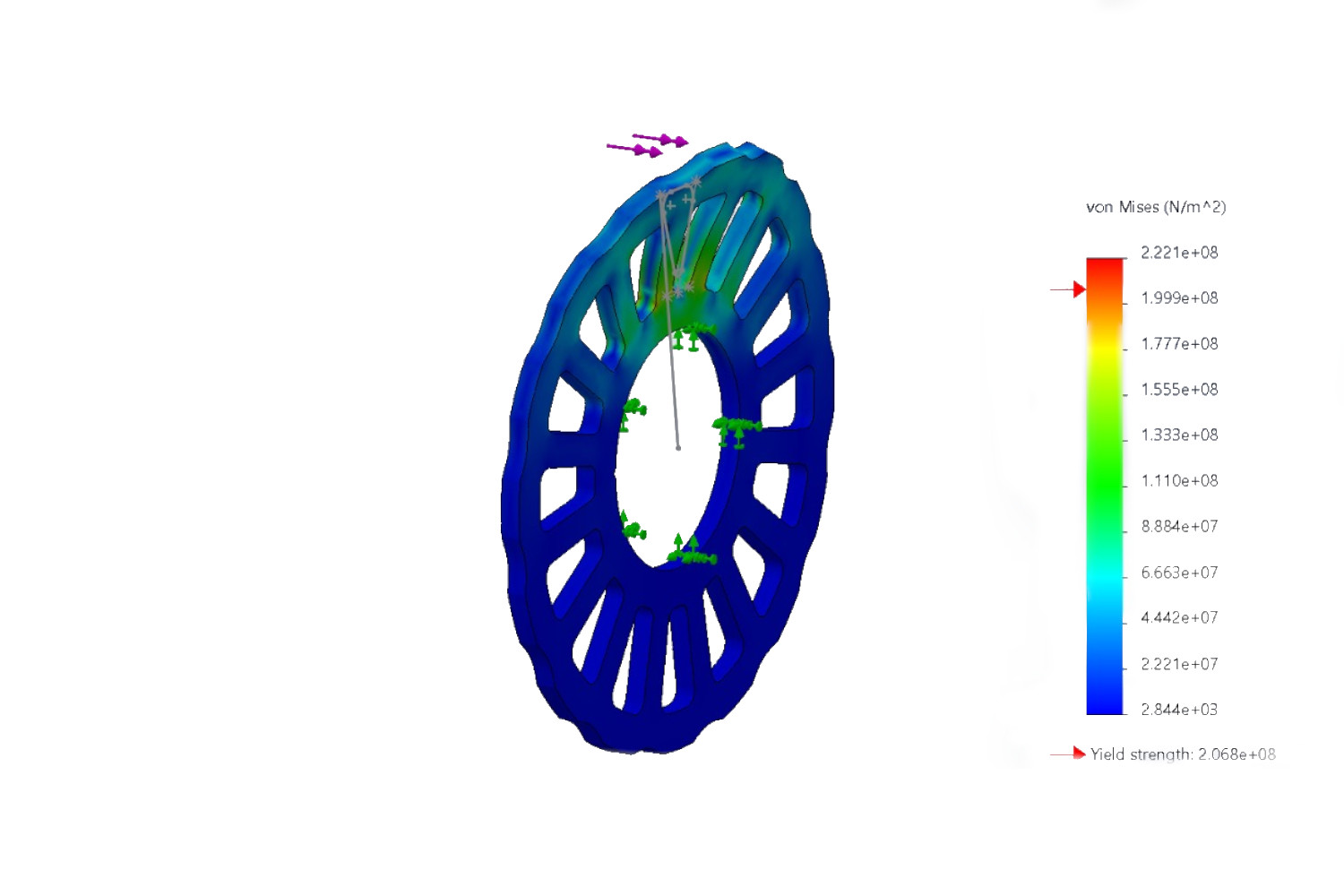

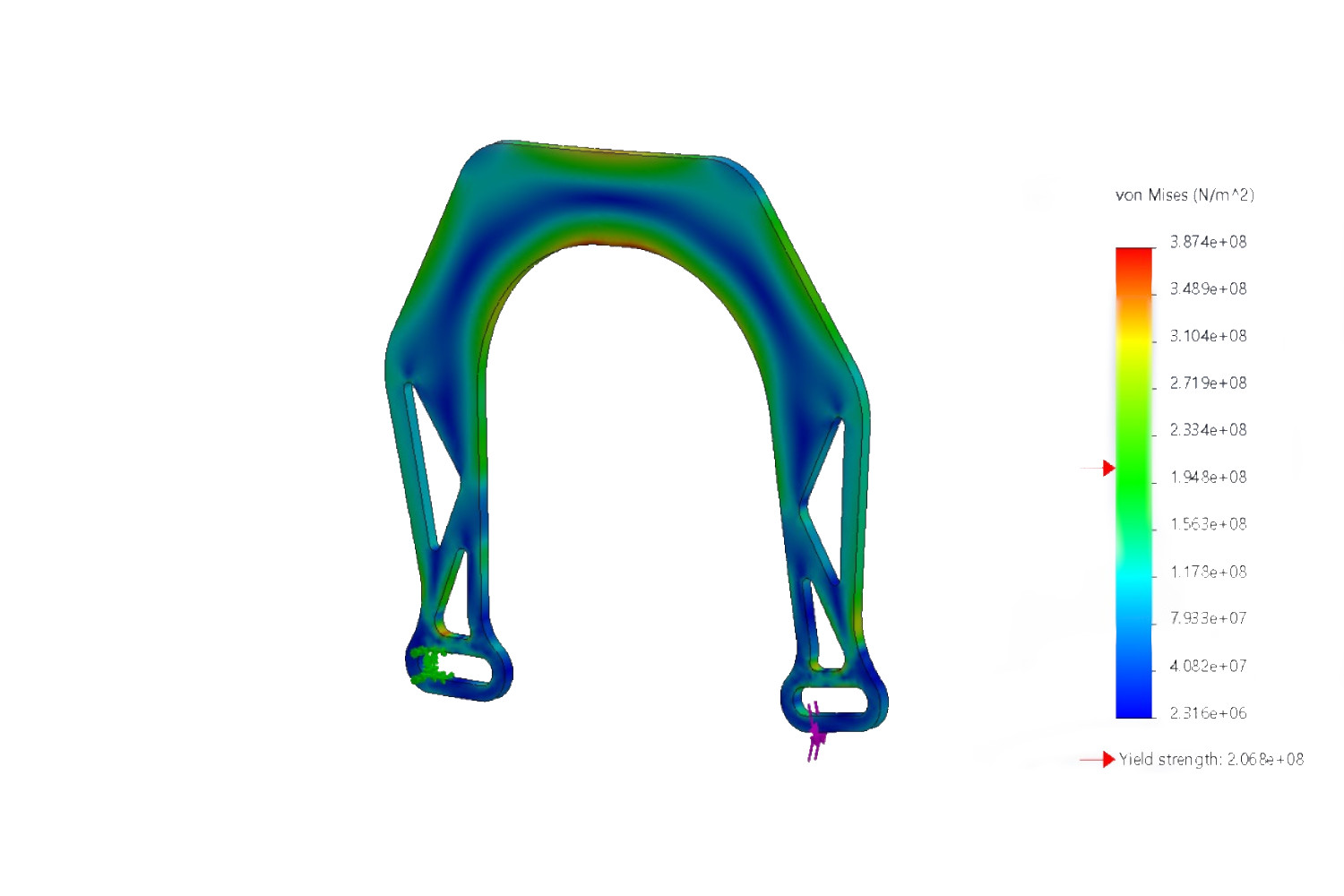

The images below show the FEA process in action. Purple arrows indicate the load direction with the colour shift indicating where stress is produced, and the areas it's most pronounced. A 'cooler' blue or green colour slows low stress, 'warmer' yellow and red colours denote higher stresses. The distribution seen here is normal for a brake booster, but the key is coming up with a design that has an even distribution around the underside where it is trying to 'stretch' from braking forces. It's also good to ensure that they are no 'hot spots' where high stress is produced, as this can cause additional flex or even a failure over time. All FEA tested products were simulated using loads well beyond what they'll see in the real world, so we know they're up to the job and offer a real performance benefit!

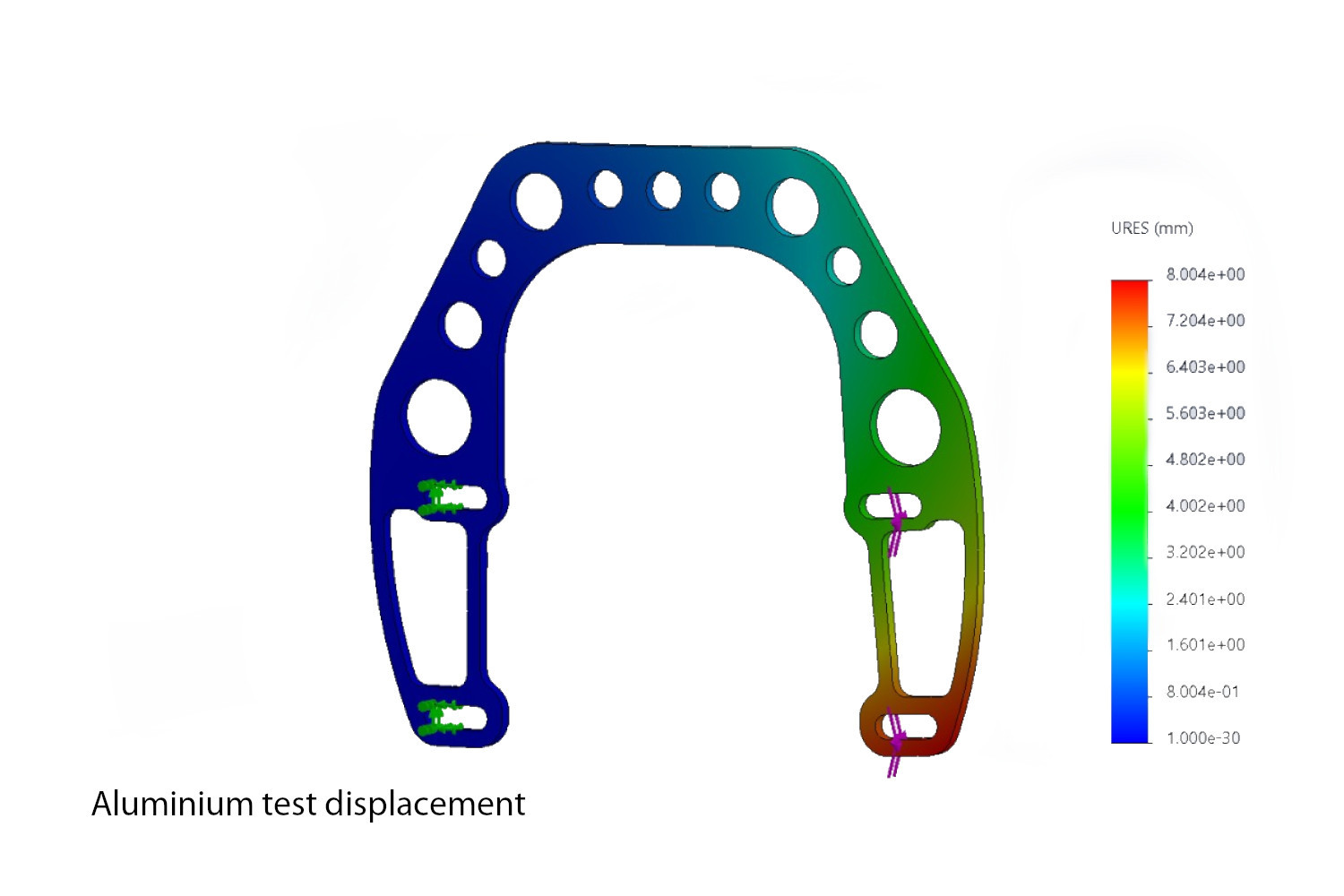

The image below shows a displacement (flex) test of an aluminium brake booster with 3mm thickness - same thickness as the one in our range. This is an earlier design that didn't make the cut as the additional holes introduced too much flex, but FEA testing showed a displacement of 8.0mm, whereas a stainless steel version was just 3.3mm. In the real world, when fitted to a bike, we tested our stainless booster to have under 0.5mm of flex even when giving the brake a full squeeze with 3 fingers!

Stainless is also really cool in that it doesn’t need any special finishing, saving cost and being better for the environment. No chemicals, dyes or pollutants are using during manufacture like you need with painting or anodising, and the mateial is completely re-cycleable if / when the time comes - even in your home recycling if necessary. Another beauty of steel vs aluminium is how it behaves if you do manage to make a real mess of things. It can simply be bent back into shape using your hands / adjustable spanner / vice, etc.

Furthermore, if you want to customise these parts then you can do that without it looking weird. Want to drill a few more holes? No worries! It’s not like doing it on a black anodised aluminium part that might scratch or look unmatched when the holes are silver. Prefer a more ‘brushed’ look? That’s cool, just get handy with the sandpaper and away you go, or get really snazzy and bust out the Autosol for a mirror finish shine. Made a mess of the edge of your bash ring? No worries, it can be tidied up with a file and sandpaper, bringing it virtually back to new again.

More products are in the pipeline, and we are beavering away behind the scenes working on things like a funky universal chain tensioner using a new concept, adjustable 4-Bolt to V-Brake adaptors, and further accessories that will help to keep your bike in working order without breaking the bank.

We hope you enjoy these parts. They are truly made ‘for riders, by riders’ – and so of course feedback is welcome. Thank you! Adam"

Technical Info

Technical InfoNew to trials? Then check out our product video guides for useful tips and technical advice

Facebook

FacebookFollow us on Facebook for exclusive deals, promo codes and offers

Need some help?

Need some help?Have a question? No problem, call us on 01772 32 33 33 or get in touch via our contact page.

TartyBikes Ltd, Units 3-4, Club Street, Bamber Bridge, Preston, PR5 6FN

Web Design & Development by tame